Email:

sales@milkplan.com

MP Milk Transfer

(TT 500lt - 4.000lt)

MP Milk Transfer transportation tanks are specially insulated stainless steel tanks which ensure stable temperature for long time periods (8-12 hours), are easily installed on vehicles of various types and allow multiple shipments from different producers. They are available in 12 models with capacities from 500lt to 4,000lt.

All types of tanks are made of food grade stainless steel AISI 304 (DIN 1.4301) and have a double wall with high density, environmentally friendly polyurethane foam thermal insulation to ensure stable temperature of the milk.

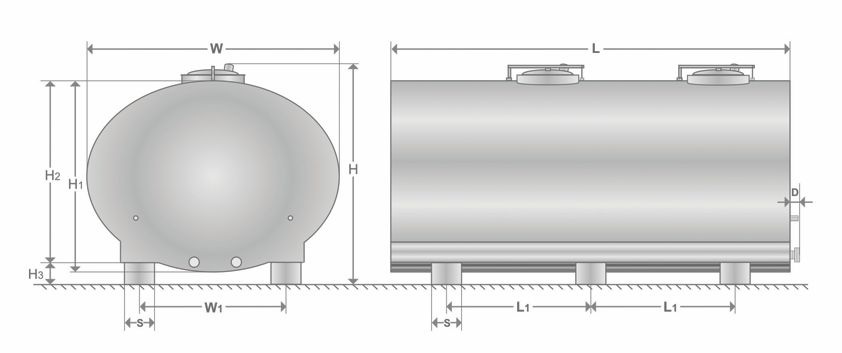

- Dimensions

- Features

- Photos

- Video

500lt - 4.000lt

| Type | Maximum capacity |

W | W1 | H1 | H2 | H3 | H | L | L1 | Number of feet |

| TT 500E | 530 | 990 | 590 | 800 | 765 | 140 | 1055 | 1250 | 740 | 4 |

| TT 750E | 800 | 990 | 590 | 800 | 765 | 140 | 1055 | 1830 | 1110 | 4 |

| TT 1000E | 1050 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 1250 | 800 | 4 |

| TT 1000E-2 | 1050 | 990 | 590 | 800 | 765 | 140 | 1055 | 2400 | 825 | 6 |

| TT 1500E | 1580 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 1830 | 1090 | 4 |

| TT 1500E-2 | 1580 | 990 | 590 | 800 | 765 | 140 | 1055 | 3550 | 1395 | 6 |

| TT 2000E | 2100 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 2400 | 825 | 6 |

| TT 2000E-2 | 2100 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 2400 | 825 | 6 |

| TT 2500E-2 | 2600 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 2950 | 1095 | 6 |

| TT 3000E-2 | 3160 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 3560 | 1400 | 6 |

| TT 3000E-3 | 3160 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 3560 | 1400 | 6 |

| TT 4000E-3 | 4180 | 1320 | 760 | 1080 | 1030 | 140 | 1320 | 4680 | 1755 | 6 |

*D: 100mm, H3: 140mm, S: 151mm

Appropriate tank design

Milkplan’s know-how in milk cooling tanks ensures simple construction, ease of use, reliable performance and long life span while offering excellent value for money.

Inner design

Robust construction, high resistance to stress with smooth inner walls, round edges and perfect welding.

Shape & construction

Thanks to the elliptical cross section of the tanks and their oval shape, all MP Milk Transfer models maintain a low center of gravity enhancing the vehicle balance during milk transportation.

Precise design & excellent cleaning

The functional design, quality and processing of the metal construction prevent the entrapment of even the minutest milk quantity inside the tank, therefore avoiding the development of bacteria and deterioration of milk quality.

Pressure equalization

Each tank has an additional stainless steel ventilation cap to allow air inlet/outlet and prevent high pressure or negative pressure during the filling or evacuation of the tank.

Complete sealing

The elevated manhole (D400mm) in combination with the gasket at the upper part, the easy locking system and the perfect welding ensure the complete sealing of the tank and the safe transportation of milk.

Robust construction

The robust construction provides resistance against transport stresses and their suitable design contributes to road safety by reducing the risk of abrupt weight shifts.

Milk separation

The partitioning of the interior in one or more compartments allows sequential and separate collection of milk quantities from different sources.

Independent outlet valves

Each compartment has its own independent outlet butterfly type valve DN50, SMS51 or Triclamp according to the needs. In case of DN50 type, the valve is equipped with a food grade plastic cap.

Easy cleaning & disinfection

Each compartment has its own sprayball system. It can optionally be combined with ΜPP Standard.

Milk pump (option)

All MP Milk Transfer tanks can optionally be equipped with the powerful stainless steel milk 230V or 12V pump for continuous circulation and constant milk flow during their filling or evacuation.

https://milkplan.com/site/index.php/en/products/transportation/mp-milk-transfer#sigProGalleriadab1c24fce