Email:

sales@milkplan.com

MP CoolMilk Transfer - Cooling with AC/Generator

(CTT 500 - 2.000lt)

The MP CoolMilk Transfer refrigerated transportation tank is a smart solution for milk transportation and cooling for a reliable and effective operation everywhere.

Made of a double wall thermal insulation with high density polyurethane foam and a full-flow heat exchanger at the lower part to support the direct expansion function, MP CoolMilk Transfer minimizes energy loss while ensuring direct dissipation of the milk's heat, avoiding the formation of ice particles.

All types of tanks are made of food grade stainless steel AISI 304 (DIN 1.4301).

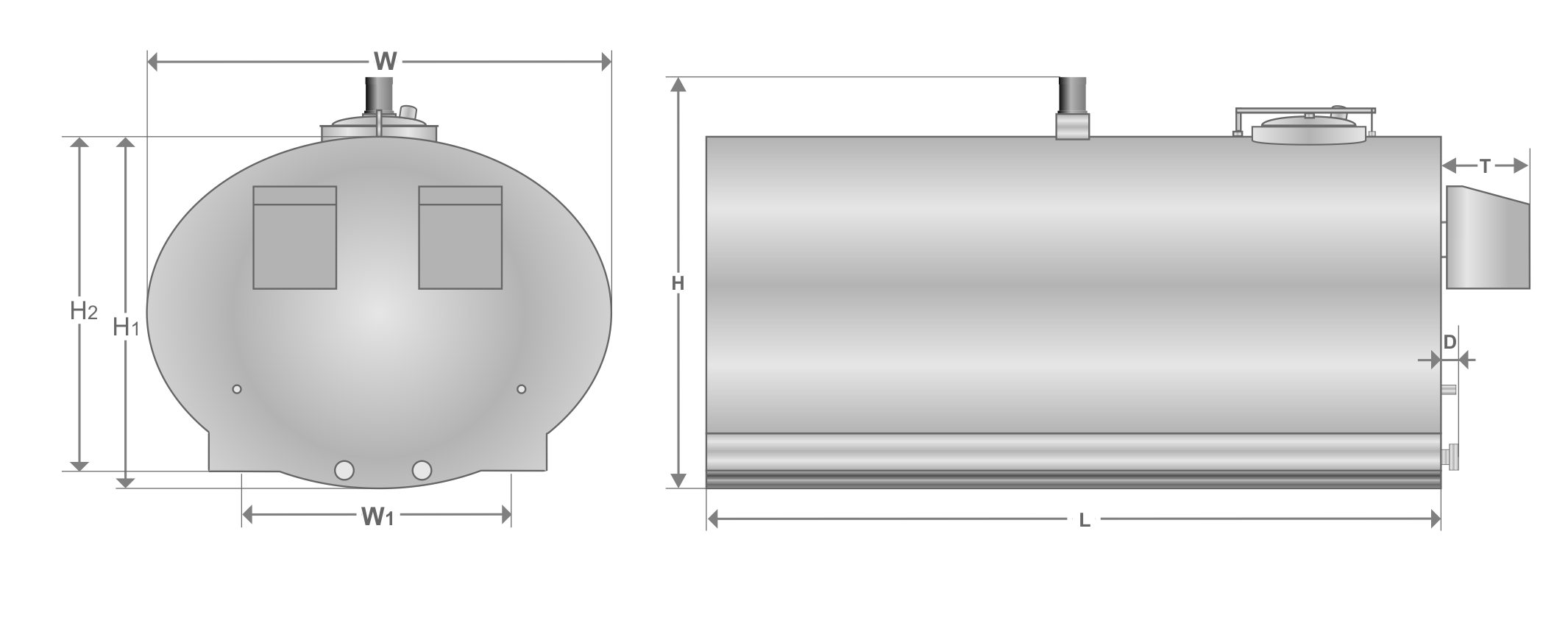

- Dimensions

- Features

- Photos

500lt - 4.000lt

| Type | Maximum capacity |

W | W1 | H1 | H2 | H | L |

| CTT 500E | 530 | 990 | 590 | 800 | 765 | 1055 | 1250 |

| CTT 1000E | 1050 | 1320 | 760 | 1080 | 1030 | 1320 | 1250 |

| CTT 1500E | 1580 | 1320 | 760 | 1080 | 1030 | 1320 | 1830 |

| CTT 2000E | 2100 | 1320 | 760 | 1080 | 1030 | 1320 | 2400 |

*D: 100mm, T: 400mm

Appropriate tank design

Milkplan’s know-how in milk cooling tanks ensures simple construction, ease of use, reliable performance and long life span while offering excellent value for money.

Inner design

Robust construction, high resistance to stress with smooth inner walls, round edges and perfect welding.

Shape & construction

Thanks to the elliptical cross section of the tanks and their oval shape, all MP Milk Transfer models maintain a low center of gravity enhancing the vehicle balance during milk transportation.

Precise design & excellent cleaning

The functional design, quality and processing of the metal construction prevent the entrapment of even the minutest milk quantity inside the tank, therefore avoiding the development of bacteria and deterioration of milk quality.

Pressure equalization

Each tank has an additional stainless steel ventilation cap to allow air inlet/outlet and prevent high pressure or negative pressure during the filling or evacuation of the tank.

Complete sealing

The elevated manhole (D400mm) in combination with the gasket at the upper part, the easy locking system and the perfect welding ensure the complete sealing of the tank and the safe transportation of milk.

Trailer

Automatic hot-dip galvanized trailer in accordance with the EU Directive on road safety and regulations. It has lights, towing and parking brakes, suspensions and an emergency wheel (spare wheel).

Agitation system

MP CoolMilk Transfer is equipped with a programmable agitation system which provides slow and gentle milk agitation. The system can be set either to automatic cyclic or continuous operation ensuring the effective cooling of the milk for the entire content of the tank as well as the preservation of milk lipids in accordance with ISO 5708 directive.

System stability

The agitation shaft is held in place at two points (both at the top and bottom of the tank) to ensure system stability even during transportation on uneven roads.

Milk outlet

For milk outlet, a stainless steel butterfly valve, of DN50, SMS51 or Triclamp type is used, according to the needs. In case of DN50 type, the valve is equipped with a food grade plastic cap.

Cooling unit

High-performance anti-shock cooling unit with low energy consumption (Scroll technology compressor) for 2 or 4 milkings. Much more silent and lighter compared to other units of the same type.

Effective washing and disinfection

Washing system made of high-quality raw materials to prevent corrosion even by the most strong disinfectants.

Powerful water pump that guarantees continuous recirculation, constant water flow and proper spray pressure.

Independent peristaltic pumps that provide the necessary supply of liquid disinfectants for perfect hygiene and cost saving.

Integrated alarm function for immediate alert in case of a problem in the pump, compressor or agitator.

Effective washing of the tanks with spray system and special rotating washing blades.

Ease of use and effective control of all functions.

Dixell electronic controller for cooling, agitation, alarm function and temperature indication of milk.

Washing controller (PLC) with fully adjustable parameters and an option for software update.

Milk pump (option)

All MP CoolMilk Transfer tanks can optionally be equipped with the powerful stainless steel milk 230V or 12V pump for continuous circulation and constant milk flow during their filling or evacuation.

*The MP CoolMilk Transfer refrigerated transportation tank is also available with a generator for milk cooling during transportation without the need for connection to an electrical power supply.

https://milkplan.com/site/index.php/en/products/transportation/mp-coolmilk-transfer/mp-coolmilk-plugin#sigProGalleria4188ae10aa