Email:

sales@milkplan.com

MP CoolMilk Transfer - Cooling with cold water

(CTT 500 - 2.000lt)

MP CoolMilkTransfer is also available in version for milk cooling with cold water 1°C. It is an ideal solution for areas where cold water is abundant in the environment since its use provides significant energy saving. The specially designed full-flow heat exchanger in the whole interior and the caps of the tank achieves the same cooling time that would be required if using a cooling unit.

All types of tanks are made of food grade stainless steel AISI 304 (DIN 1.4301).

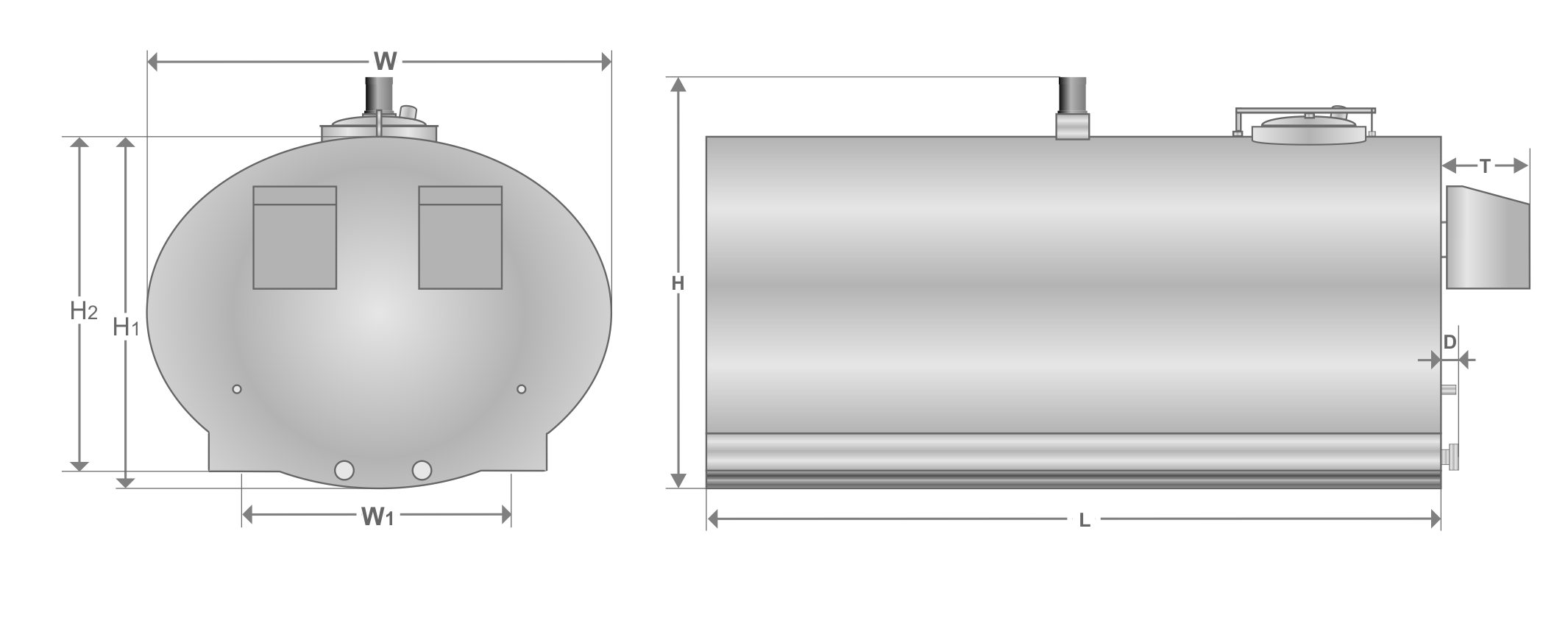

- Dimensions

- Features

- Photos

500lt - 2.000lt

| Type | Maximum capacity |

W | W1 | H1 | H2 | H | L |

| CTT 500E | 530 | 990 | 590 | 800 | 765 | 1055 | 1250 |

| CTT 1000E | 1050 | 1320 | 760 | 1080 | 1030 | 1320 | 1250 |

| CTT 1500E | 1580 | 1320 | 760 | 1080 | 1030 | 1320 | 1830 |

| CTT 2000E | 2100 | 1320 | 760 | 1080 | 1030 | 1320 | 2400 |

*D: 100mm, T: 400mm

Appropriate tank design

Milkplan’s know-how in milk cooling tanks ensures simple construction, ease of use, reliable performance and long life span while offering excellent value for money.

Inner design

Robust construction, high resistance to stress with smooth inner walls, round edges and perfect welding.

Shape & construction

Thanks to the elliptical cross section of the tanks and their oval shape, all MP Milk Transfer models maintain a low center of gravity enhancing the vehicle balance during milk transportation.

Precise design & excellent cleaning

The functional design, quality and processing of the metal construction prevent the entrapment of even the minutest milk quantity inside the tank, therefore avoiding the development of bacteria and deterioration of milk quality.

Complete sealing

The elevated manhole (D400mm) in combination with the gasket at the upper part, the easy locking system and the perfect welding ensure the complete sealing of the tank and the safe transportation of milk.

Agitation system

MP CoolMilk Transfer is equipped with a programmable agitation system which provides slow and gentle milk agitation. The system can be set either to automatic cyclic or continuous operation ensuring the effective cooling of the milk for the entire content of the tank as well as the preservation of milk lipids in accordance with ISO 5708 directive.

System stability

The agitation shaft is held in place at two points (both at the top and bottom of the tank) to ensure system stability even during transportation on uneven roads.

Pressure equalization

Each tank has an additional stainless steel ventilation cap to allow air inlet/outlet and prevent high pressure or negative pressure during the filling or evacuation of the tank.

Milk outlet

For milk outlet, a stainless steel butterfly valve, of DN50, SMS51 or Triclamp type is used, according to the needs. In case of DN50 type, the valve is equipped with a food grade plastic cap.

Milk pump

All Mp CoolMilkTransfer tanks are equipped with a powerful 230V or 12V stainless steel milk & washing pump for continuous circulation and constant flow. Equipped with a special stainless steel base and adapters for easy & quick use.

Milk separation

The partitioning of the interior in one or more compartments allows sequential and separate collection of milk quantities from different sources. In this case, one compartment has an exchanger for cooling and the other has insulation for maintaining the temperature.

Exchanger filter

A specially designed stainless steel filter for cleaning the water before entering and circulating the exchanger for protection against wear.

Trailer (optional)

Automatic hot-dip galvanized trailer in accordance with the EU Directive on road safety and regulations. It has lights, towing and parking brakes, suspensions and an emergency wheel (spare wheel).

Ease of use and effective control of all functions

Stainless steel electronic temperature control panel with optional operation of the combinational cooling tank.

Dixell electronic controller for cooling, agitation, alarm function and temperature indication of milk.

**Available with built-in hooks for easy installation.

https://milkplan.com/site/index.php/en/products/transportation/mp-coolmilk-transfer/mp-coolmilk-water#sigProGalleria0007218835